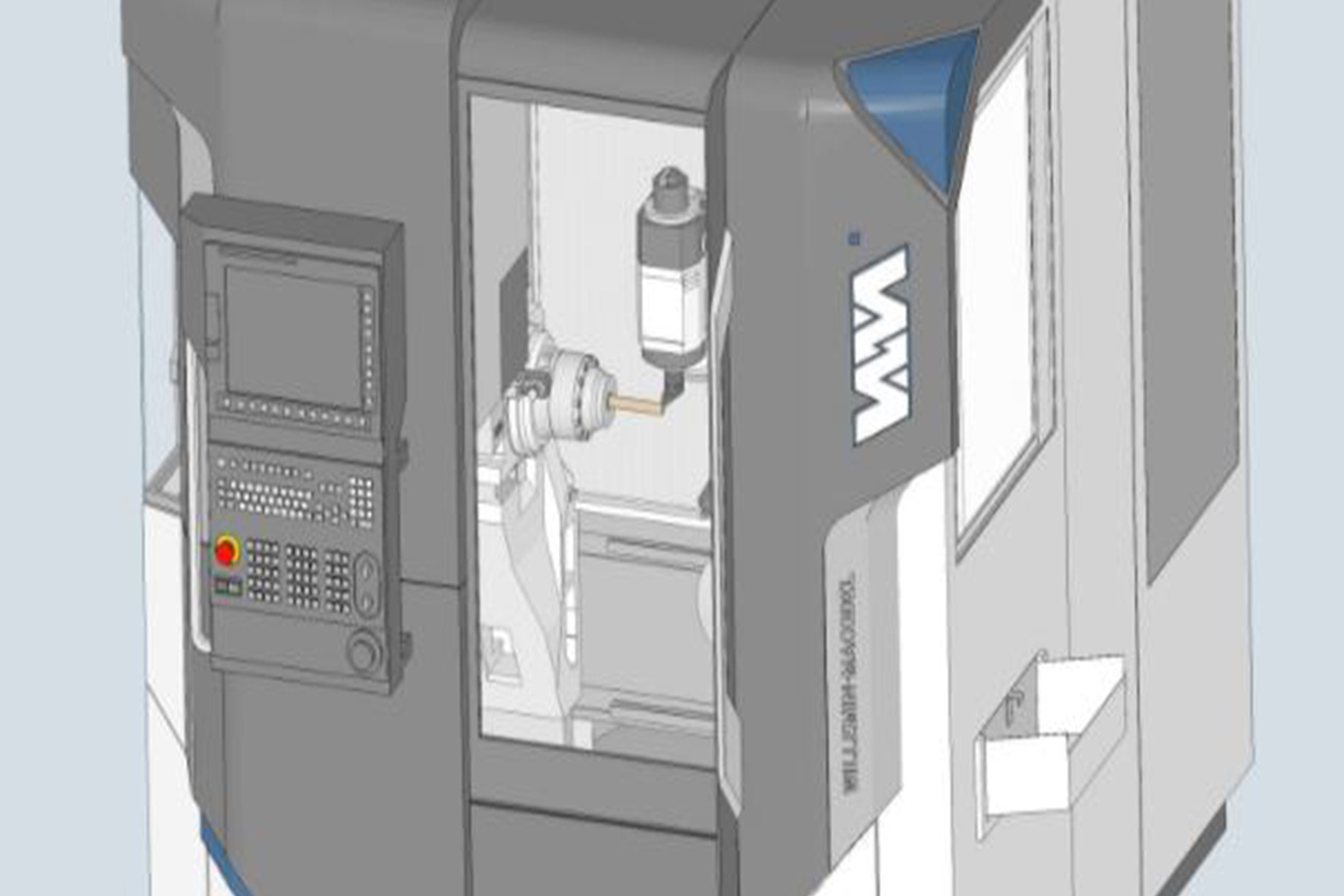

Pioneer of innovative machining solutions

Since 1974, we translate the needs of our customers into productivity gains

For each request, Willemin-Macodel develops a unique solution. This is how our experience and technologies enable us to meet the specific needs of our customers.

Innovation and Tradition at the Heart of SIAMS 2024

Innovation and Tradition at the Heart of SIAMS

Willemin-Macodel : Innovation and Tradition at the Heart of SIAMS 2024

FIND OUT MORECustom Manufacturing Solutions with Willemin-Macodel and ESPRIT update 09.12.2022

Custom Manufacturing Solutions with Willemin-Macodel and ESPRIT

Willemin-Macodel and ESPRIT CAM work together to realize the full potential of machining centers

FIND OUT MOREOverhaul of Willemin-Macodel machines

Revision of machines

The purchase of a Willemin-Macodel’s machine is a long-term investment and far beyond ...

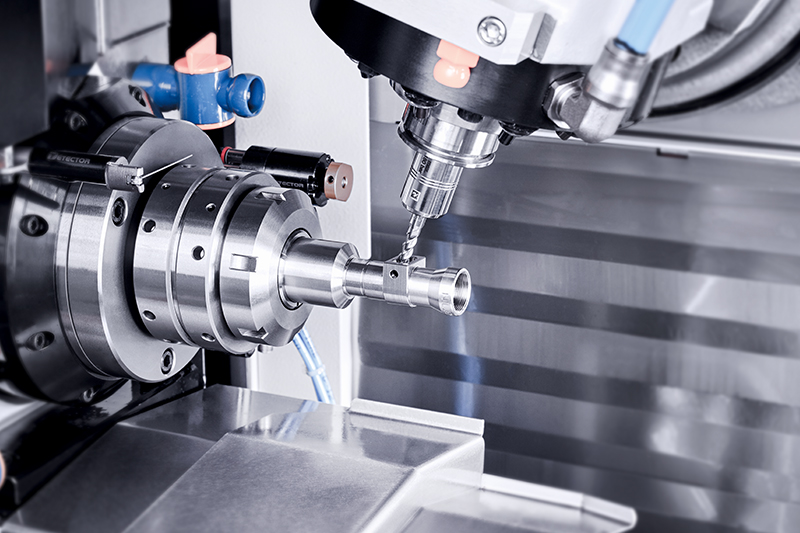

FIND OUT MOREMulti-process machining from bar stock 24.11.2020

Multi-process machining from bar stock

The very high demands of the markets, the trades as well as the complex manufacturing and production criteria, accompany Willemin-Macodel in the development of complete solutions.

FIND OUT MOREInnovation

Constant innovation, absolute precision

Offering its customers perfectly tailored solutions, Willemin-Macodel creates ultra-precise equipment for various fields in the microtechnology manufacturing sector.

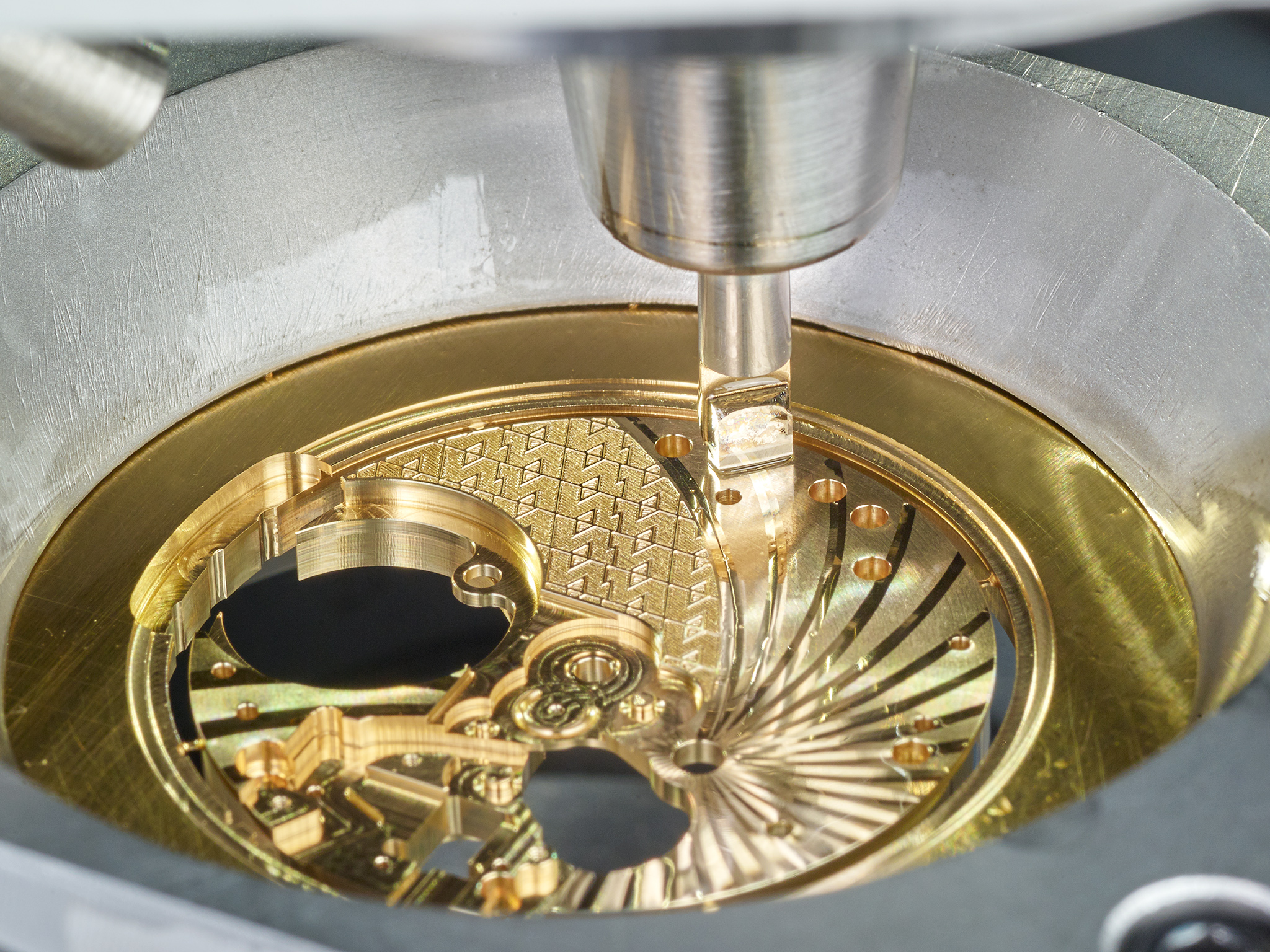

FIND OUT MOREWatchmaking sector

A fully mastered machining process for the watchmaking sector

Focus on two solutions particularly suited to watchmaking applications: the 701S, for extraordinary movement parts, and the 308S2 5-axis machining center.

FIND OUT MOREAutomation

From the machining center to the complete automated 4.0 solution

At EMO, German and international customers can discover how Willemin-Macodel creates Swiss made custom machining solutions, highly competitive and meeting all types of needs.

FIND OUT MOREAutomation

Automatic production cell

Producing by the unit with the advantages of large-scale production

FIND OUT MORETHE EXPERTS IN COMPLEX, HIGH-PRECISION PARTS

No matter what part you want to produce, we'll find you the right solution. Small/large scale and even single unit production

Flat parts

The machining spindle occupies a single orientation in relation to the part for all machining operations on a single face. By turning over the part, it is possible to machine a second associated face which will necessarily be parallel to the top face

Polyhedral parts

The machining spindle's access to all sides of the individual polyhedron means the machine must have extra axes. In most cases, consideration must be given to how the part is gripped, which will reduce the machining spindle's access to all the machining sides, mainly the contact side.

Complex parts

The part should be positioned so that the spindle can access all the faces of the polyhedron. It should be able to be rotated quickly around its axis of symmetry in order to be able to create cylindrical revolution surfaces and internal or external diameters by turning.

solution finder

solution finder