COMMITMENT OF A LEADER FOR 50 YEARS

Willemin-Macodel is a supplier of innovative machining and robotization solutions. Independent company, located in Delémont in the Jura and at the heart of microtechnology. Our objective is clear : to meet your highest requirements. We design flexible, dynamic and productive solutions based on a perfect understanding of your requirements. Leader and expert in turnkey machining solutions, Willemin-Macodel is committed to you.

Does the 701S live up to its promise?

Discover the testimony of the company Vaucher Manufacture Fleurier, which owns a large fleet of 701S micromachines. The vision and pioneering spirit of this prestigious engine builder led to a very close collaboration with Willemin-Macodel, enabling the 701S's formidable potential to be exploited to the full.

Our warmest thanks to Messrs Lefevre, Chanal, Gonzalez and Wenger for their testimonials and availability. We are very proud of this collaboration.

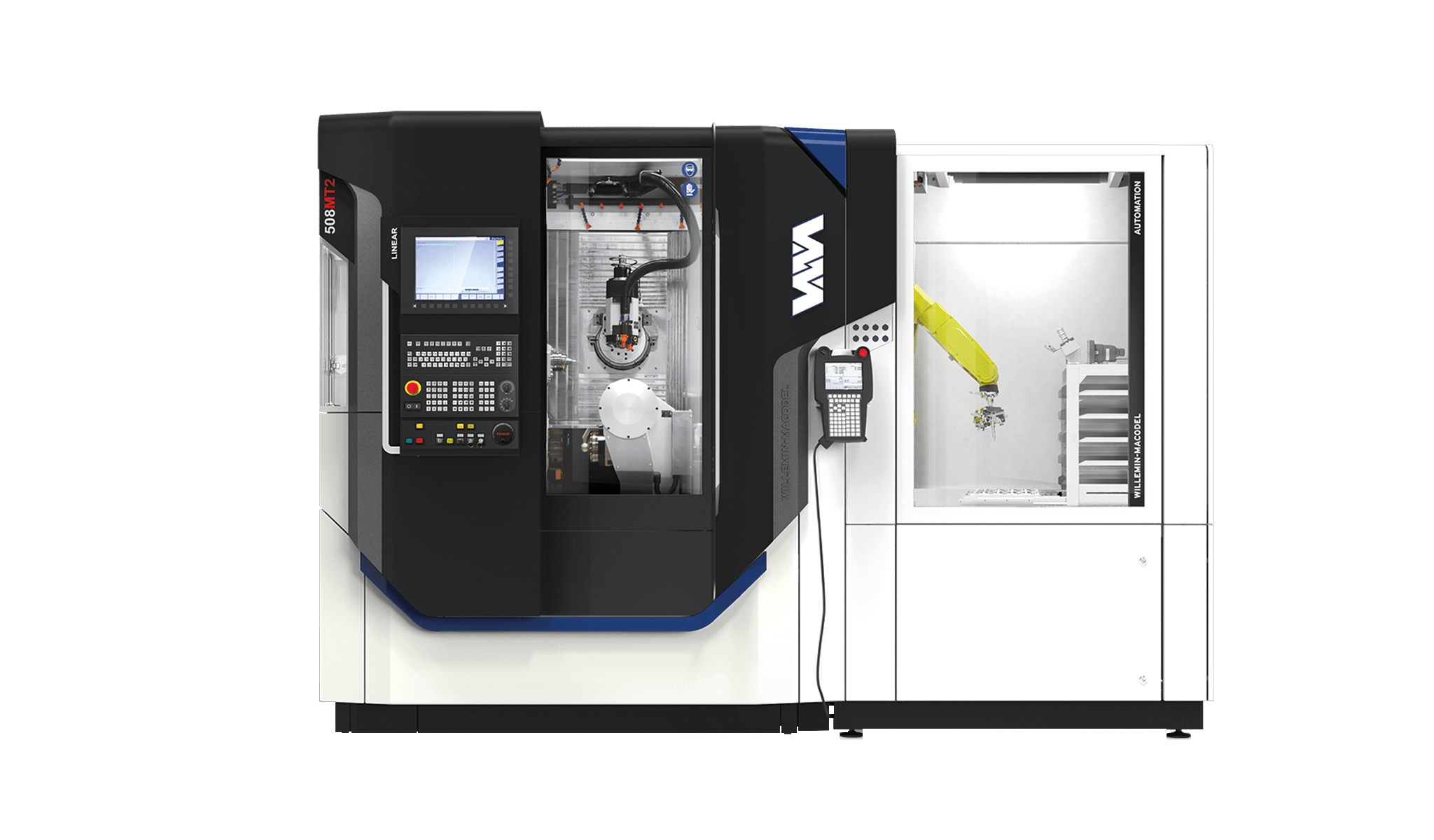

" Since we got the 508MT2, we have never had to do a secondary operation "

Here's a new testimonial from AFT Micromécanique, a company specialized in the manufacture of medical devices, with whom we've been working for many years, and even more so since the establishment in the new facility in Courgenay in the canton of Jura. Your sharing of experience enriches our know-how and enables us to push back the limits of technology.

Many thanks to Jérôme Frésard, CEO, Nicolas Jolivet, COO, Fabien Jacquet, Workshop Manager and Marceau Toitot, Multiaxis Center Setter, for their testimonials, and to the entire AFT Micromécanique team..

Expertise passed on to the next generation

Willemin-Macodel's innovative attitude is a key dimension in setting itself apart. But innovation isn't just about technology! The human aspect plays an essential role. With this in mind, our company has been committed since 1974 to creating a climate conducive to long-term cooperation with our employees. What's more, we are proud to invest in the training of our apprentices, enabling them to develop in an environment conducive to the transmission of unique know-how.

Technical Trades Training

Pioneer of innovative machining solutions

Since 1974, we translate the needs of our customers into productivity gains

Willemin-Macodel develops unique solutions for each individual order. This is how our experience and technologies enable us to meet the specific needs of our customers.

Innovation and Tradition at the Heart of SIAMS 2024

Innovation and Tradition at the Heart of SIAMS

Willemin-Macodel : Innovation and Tradition at the Heart of SIAMS 2024

Custom Manufacturing Solutions with Willemin-Macodel and ESPRIT update 09.12.2022

Custom Manufacturing Solutions with Willemin-Macodel and ESPRIT

Willemin-Macodel and ESPRIT CAM work together to realize the full potential of machining centers

Overhaul of Willemin-Macodel machines

Revision of machines

The purchase of a Willemin-Macodel’s machine is a long-term investment and far beyond ...

SUPPORTING YOU FROM DAY ONE

We offer our full range of expertise right from initial contact. We are experts in pairing tools and materials, machining procedures and also clamping equipment. We take care of the final tests, perform commissioning then monitor each machine throughout its service life.

STAGES

All projects need to be managed. That’s why we work in close partnership with our customers to ensure that the required solution fulfils the objectives, even if the project changes during the process.

CUSTOMER REQUIREMENTS

Studying drawings, own specifications, machining economy and management methods.

TECHNICAL ANALYSIS

Morphological analysis of the parts to be produced, topology and metrics, tolerancing and surface finishes

FEASIBILITY STUDY

Part modelling, definition of part/machine interfaces, machining strategy, operating procedure

PROJECT DEFINITION

Defining the machine and the required degree of freedom, space configuration

CLAMPING METHODS & CUTTING TOOLS

Defining gripping surfaces, studying clamping methods and defining cutting tools in accordance with the operating procedure

CUSTOMIZATION. DESIGN & SOLUTION

Detailed study of the machine with workpiece infeed/outfeed, tool changer, swarf/cutting fluid processing and protection

AUTOMATION/ROBOTIZATION

Defining and studying automation based on the customer’s production management process

PROGRAMMING & CONNECTIVITY

Creating the human/machine interface, management software for the production cell and workpiece programs. Integrating the customer’s machines in the cell (Industry 4.0)

MACHINING PROCESS

Developing and validating the complete production process integrated in the customer’s production workflow

LONG-TERM SUPPORT

Technical support, preventive and remedial maintenance, supply of spare parts throughout the product’s service life

THE EXPERTS IN COMPLEX, HIGH-PRECISION PARTS

No matter what part you want to produce, we'll find you the right solution. Small/large scale and even single unit production

Flat parts

The machining spindle occupies a single orientation in relation to the part for all machining operations on a single face. By turning over the part, it is possible to machine a second associated face which will necessarily be parallel to the top face

Polyhedral parts

The machining spindle's access to all sides of the individual polyhedron means the machine must have extra axes. In most cases, consideration must be given to how the part is gripped, which will reduce the machining spindle's access to all the machining sides, mainly the contact side.

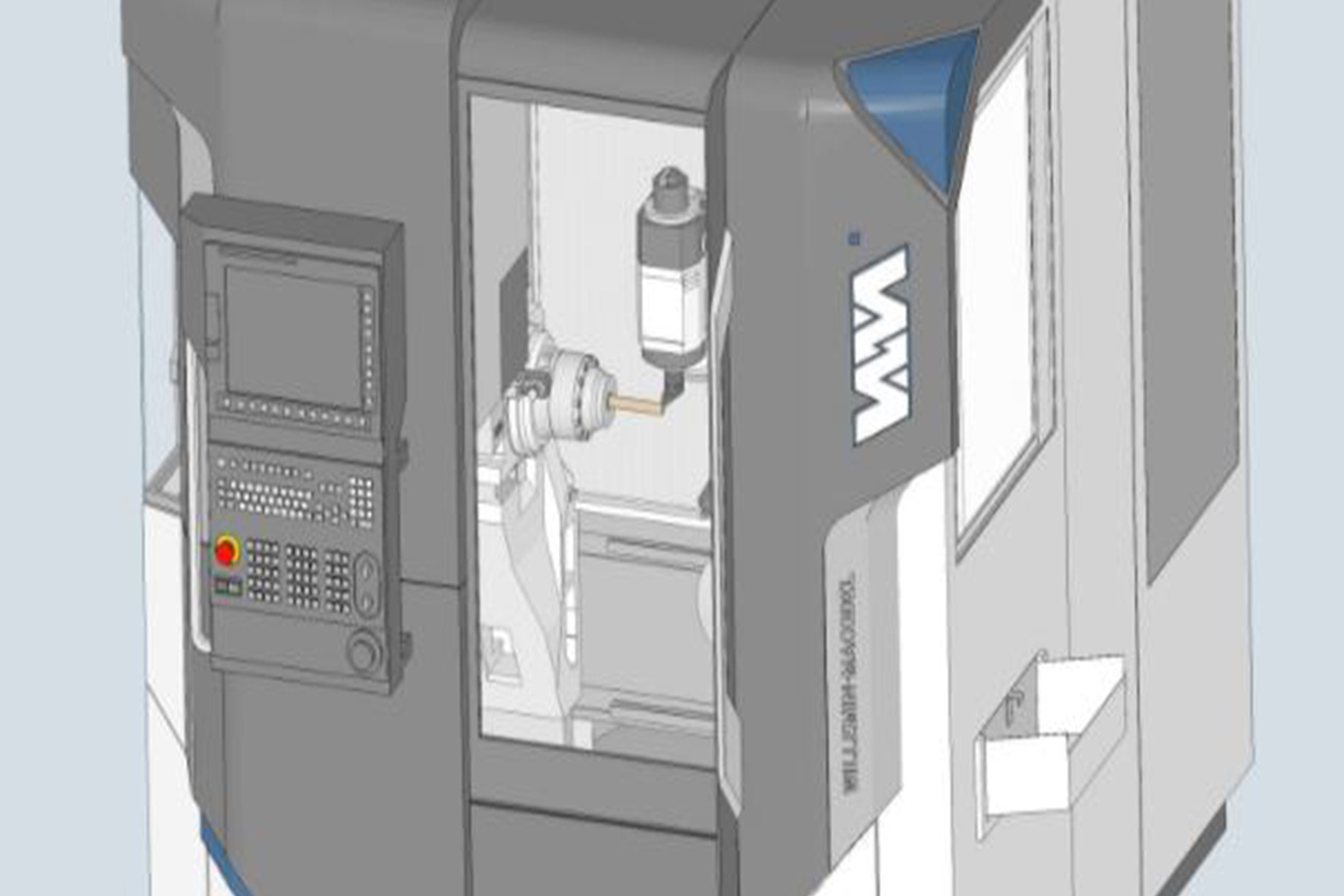

Complex parts

The part should be positioned so that the spindle can access all the faces of the polyhedron. It should be able to be rotated quickly around its axis of symmetry in order to be able to create cylindrical revolution surfaces and internal or external diameters by turning.

Coming up

News and events

14 Oct

14 Oct

MECSPE

The reference fair for the manufacturing industry

Bologne

14.10.2025 - 16.10.2025

solution finder

solution finder