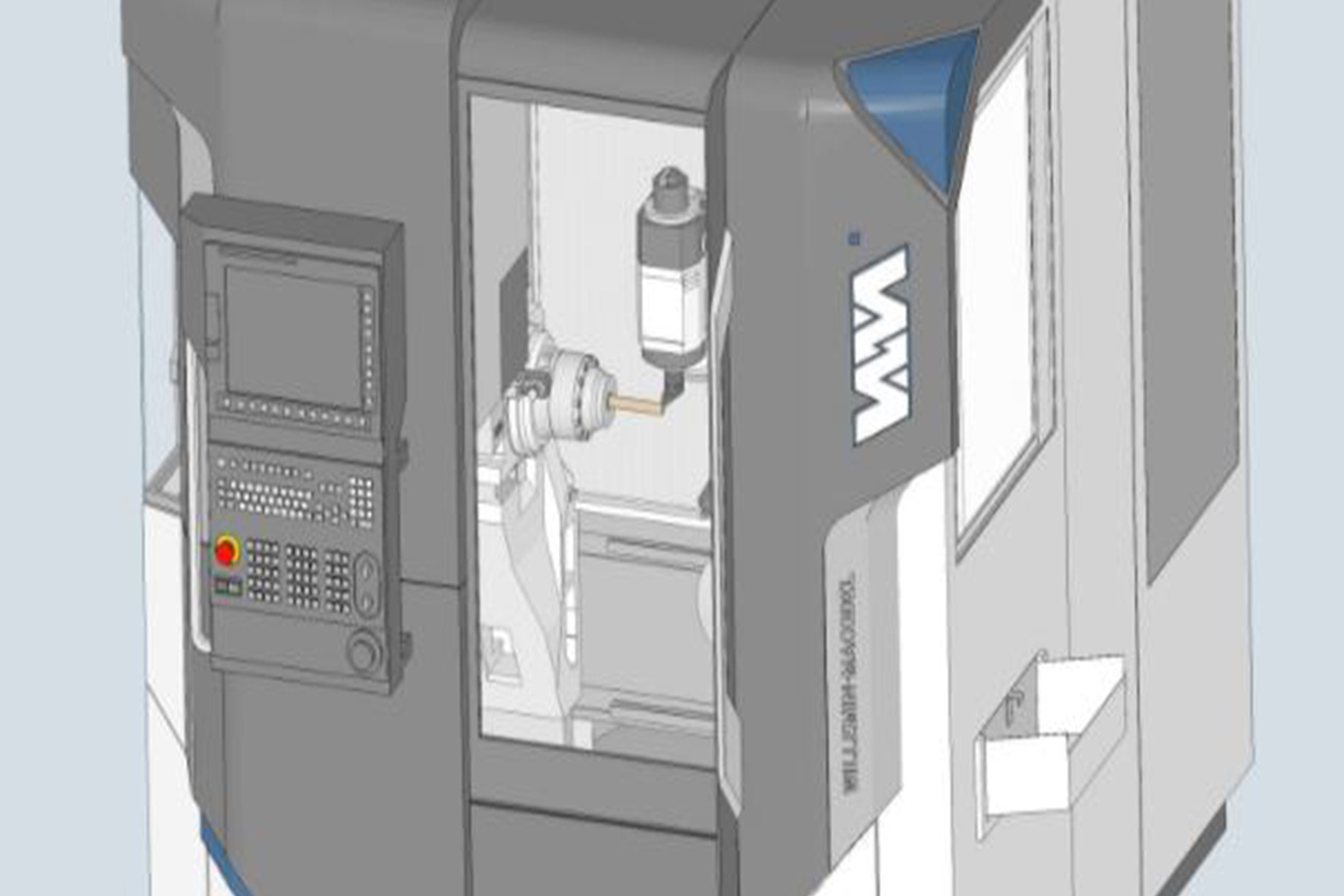

main characteristics

- Milling up to 42,000 rpm

- Turning on the C axis up to 4000 rpm

- High-precision direct drive dual divider, resolution 0.0001°

- B axis angular movement -110° to +30°

- Rapid feed rate of X Y Z linear axes, 60 m/min

DESCRIPTION

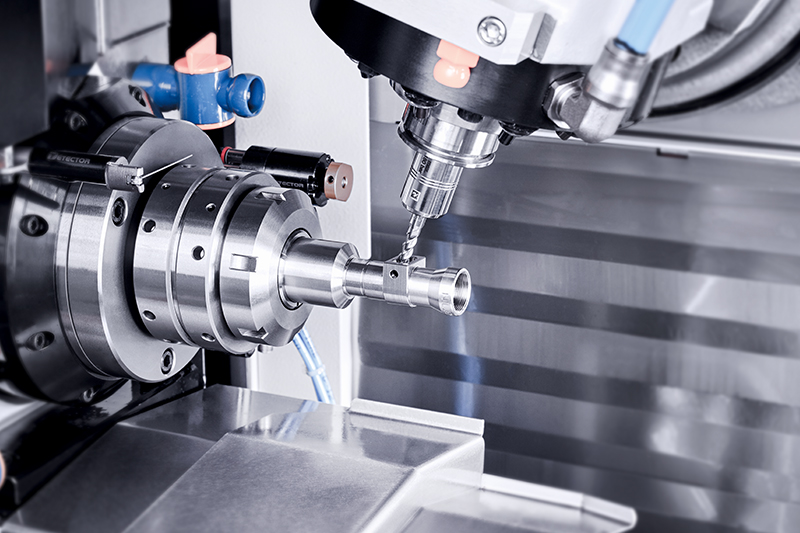

The 508S2 is a machining center with 5 simultaneous axes designed to machine complex prismatic workpieces. It benefits from "Full Linear" technology – all the linear and rotary axes are equipped with direct drive motors. Thanks to its dynamic performance and very stable temperature, the 508S2 is a highly productive machine for manufacturing high added-value parts requiring great precision and premium quality surface finishes.

The 508S2 machining center is fitted with a vertical powered spindle for milling operations at up to 42,000 rpm, and a dual rotary divider for turning operations on the C axis at up to 4000 rpm. It includes many customized features, including a tool magazine offering up to 96 positions, or custom-developed robotization. This makes the 508S2 a real multi-process machining center.

Benefiting from the latest technological developments and Willemin-Macodel's comprehensive expertise in high-precision machining on 5 simultaneous axes, the 508S2 is perfect for cutting-edge industries such as watchmaking, jewelry, medical, dental, aerospace and high-precision mechanical sub-contracting.

Other characteristics

- Milling up to 42,000 rpm

- Powered spindle, 0 - 30,000 rpm in 0.8 s

- Turning on the C axis up to 4000 rpm

- High-precision direct drive dual divider, resolution 0.0001°

- B axis angular movement -110° to +30°

- B axis indexing from 0 ° - 90 ° in 0.2 sec

- Acceleration of X Y Z linear axes, 10 m/s2

- Rapid feed rate of X Y Z linear axes, 60 m/min

- Tool magazine with up to 96 tools

- Tool change time 0.8 sec

- Central coolant programmable up to 80 bar

- Footprint approx 3.8 m2

- Direct drive of the X, Y and Z axes by linear motors, feed rate 60 m/min

- 30,000 rpm powered spindle with HSK-E40, HSK-A40 or Capto C4 interface (42,000 rpm milling as an option)

- Direct drive dual divider with 180 mm diameter plate (turning up to 4000 rpm as an option)

- Fanuc 31i-B5 or Heidenhain TNC 640 NC control console with 15’’ screen

- Tool magazine with 48-position quick changer (72 or 96-position magazine as an option)

- Various automation/robotization systems, loading or unloading of workpieces or pallets (can be adapted on the right-hand side of the machine)

- Swarf and cutting fluid recovery tray (recovery of precious metals,filtration systems or conveyor as an option)

solution finder

solution finder