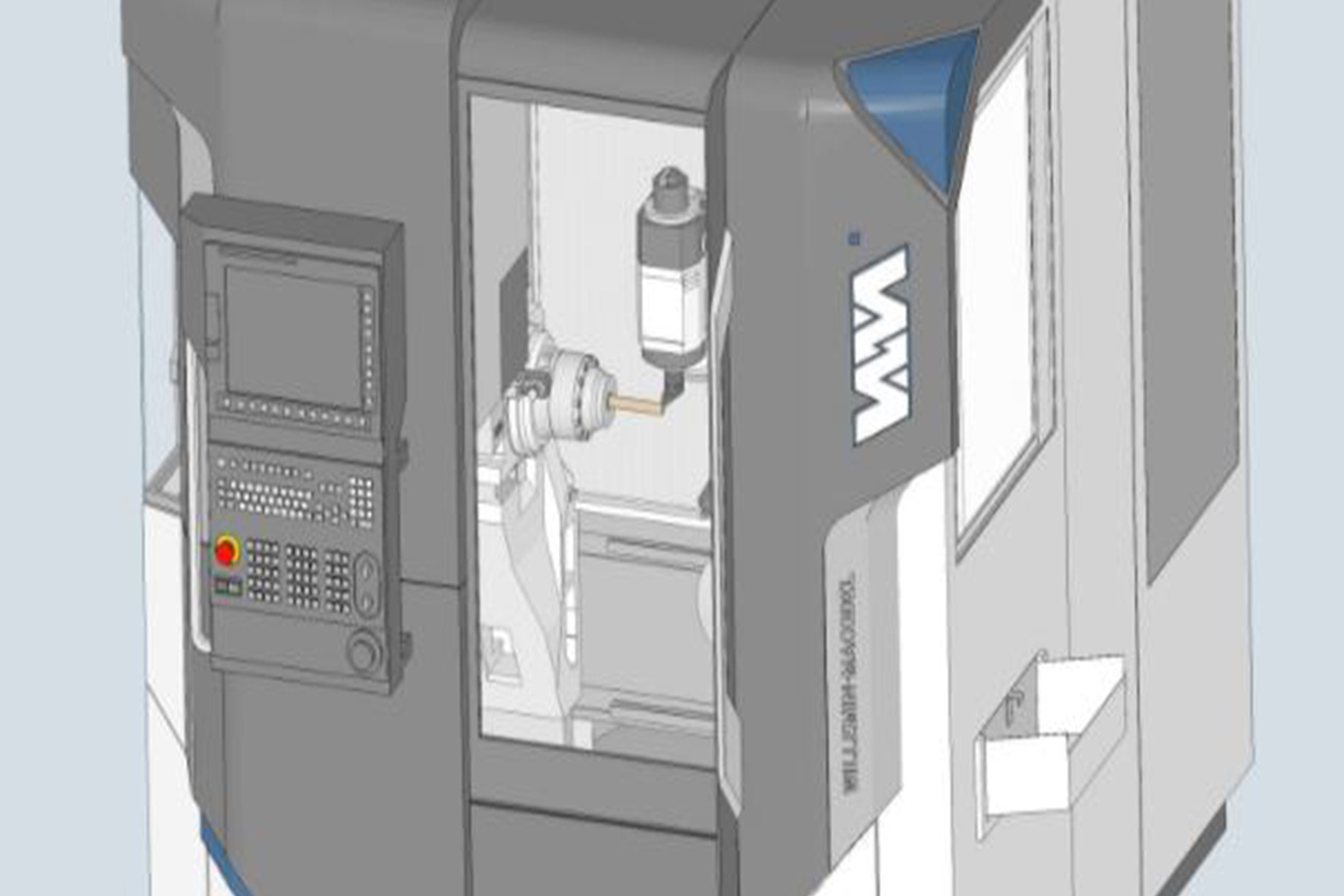

111LMC

The 111LMC (laser micro-cut) is a 3-axis laser machining center with highly dynamic interpolation of the X and Y axes. This machine is dedicated to ultra high-precision laser cutting of materials such as conventional metals, hard metal, and silicon

- 3 axes

- Laser cutting

- Laser

main characteristics

- Laser power of 2 kW / 3 kW

- Feed rate during form cutting of 5 m/min

- Cutting precision of ± 2 µm

- Drilling of holes, for example: Ø 0.1 mm for a thickness of 0.1 mm, Ø 0.3 mm for a thickness of 6 mm (Inconel)

- Diameter of water jet 30 - 80 µm

DESCRIPTION

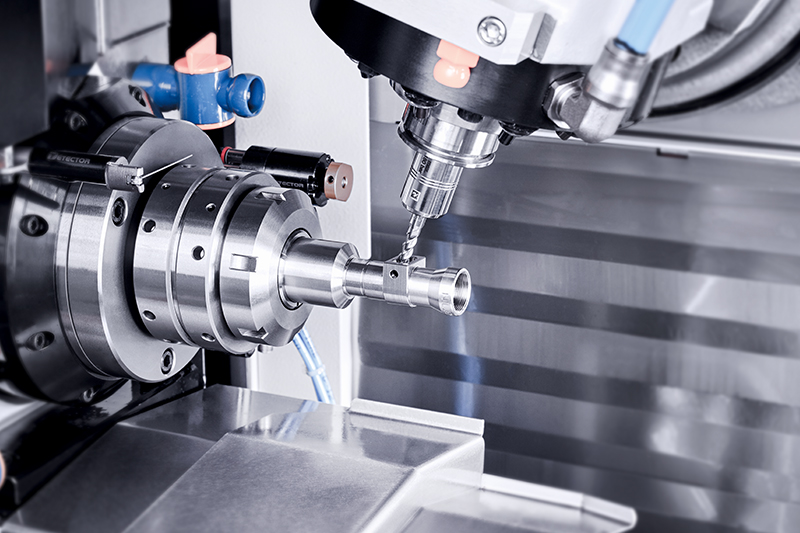

The 111LMC (laser micro-cut) is a 3-axis laser machining center with highly dynamic interpolation of the X and Y axes. This machine is dedicated to ultra high-precision laser cutting of materials such as conventional metals, hard metal, and silicon.

It is equipped with a laser head guided by a water jet in the vertical position and a large high-precision perforated and tapped table. With these two benefits, the 111LMC can offer new machining possibilities, such as ultra-precise drilling and cutting operations thanks to the perfectly straight laminar water jet with a narrow diameter, which acts as a guide for the laser beam.

It can both guarantee compliance with very narrow tolerances, and ensure high surface finish quality: two of the many reasons the 111LMC is the perfect machine for laser-cutting complex parts with both small and large dimensions.

Benefiting from the latest developments in technology and all of Willemin-Macodel's expertise in high-precision machining, the 111LMC is the ideal solution for cutting-edge applications.

Other characteristics

- Hole lengths up to 12 times the diameter

- High-precision table, dimensions 1050 x 450 mm

- Maximum acceleration of 2 g during X-Y interpolation

- Footprint approx. 2.5 m2

- Laser cutting head, max. power 3000 W. De-ionization and degassing with special cartridges

- Perforated and tapped table with dimensions of 1050 x 450 mm (697 x M6)

- Console with dedicated NC/laser process control screens

- Simple, user-friendly interface dedicated to the laser process

- Stainless steel container collects the water and protects the entire workspace from corrosion

- Specific window specially adapted to the wavelength of the laser source

solution finder

solution finder