4 April 2019

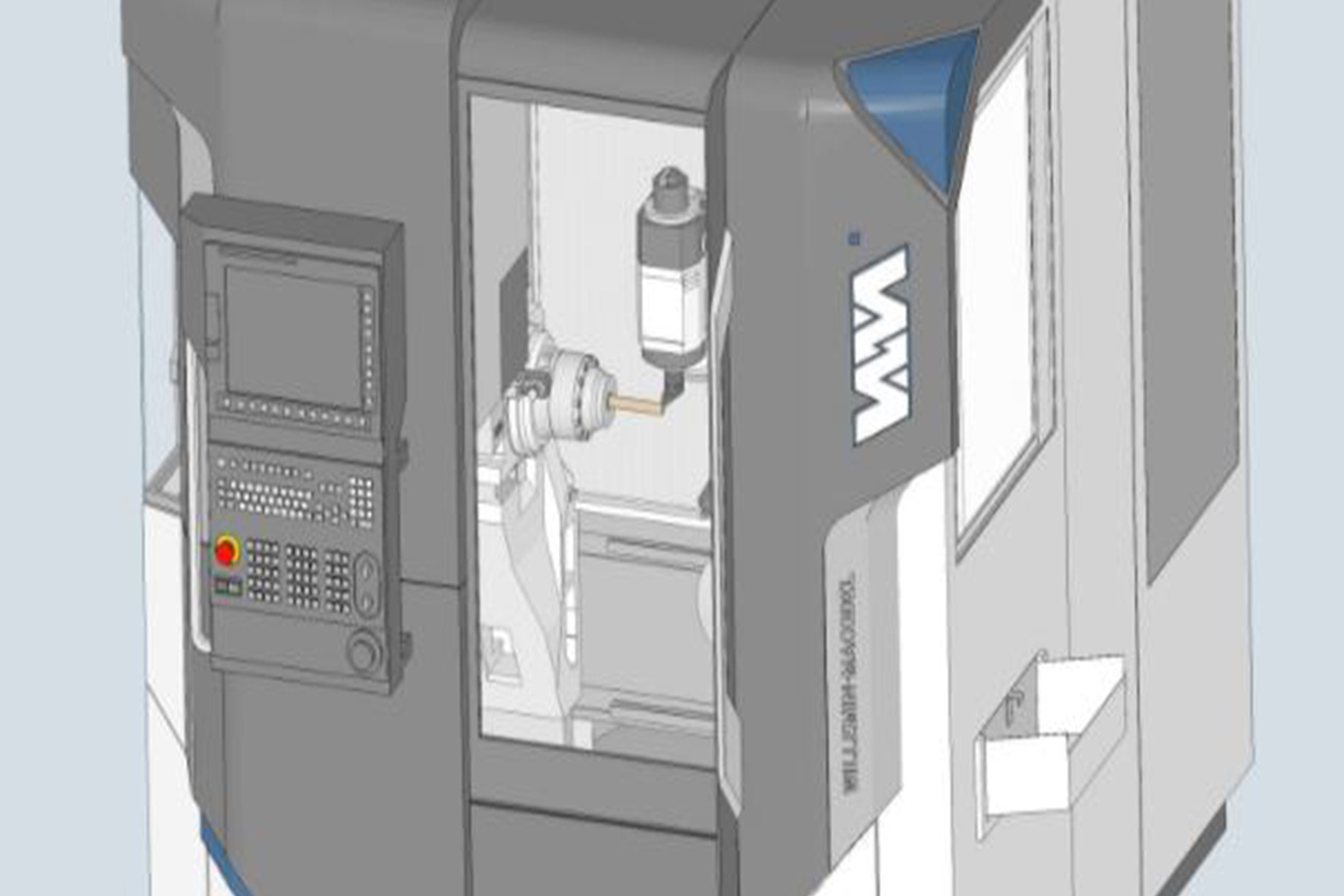

Automatic production cell

The trend is obvious. Every day, Willemin-Macodel's customer base demands increasingly customized solutions requiring more flexibility, but simultaneously guaranteeing very high production and profitability levels. How can a manufacturer of high-precision machining centers meet this ever increasing demand? Our answer is simple: by changing business direction!

Automation

Revolutionized single unit production

To achieve these new objectives, we have completely changed our business direction. We understood that our role needed to shift from manufacturer of machines to supplier of flexible integrated production cells. Starting from a common base, each part must be unique. To achieve this result, the production cell must perform a shorter process chain, with extreme flexibility and perfection in terms of quality. Complete production traceability must also be guaranteed. We have done this with an entirely new cell which we have just supplied, aimed at the medical engineering field. Designed to produce single parts or very small runs of parts, it conserves all the production conditions where large scale is key.

Supporting progress in the medical engineering field

This success is not negligible. The demand for reconstructive surgery and prosthetic implants is constantly rising. Recent advances have significantly improved and continue to optimize anatomical restoration. On the one hand, this involves choosing morpho-adapted or customized prostheses and, on the other hand, custom manufacturing tailored to data provided by a preoperative scan of the patient. Perfectly-sized implants demonstrate considerable progress: they offer better comfort and a more natural sensation. Thanks to minimally invasive surgical techniques, morpho-adapted implants not only reduce operating times, they also allow patients to return to an active lifestyle more quickly. Our new cell has allowed us to respond to the rapid development in this particular context.

A complete autonomous cell

The loading system of this new solution comprises a blanks magazine with excellent storage capacity. Under the control of high-performance production software, the robot takes the blank and checks its conformity with the 3D drawing of the part (loaded in its database) to ensure that there is no mix-up. As soon as it receives the go-ahead, the software loads the program for the part being machined in the free machine (this cell comprises two machines) and machining can commence. Once machining is complete, the part is checked and laser-marked. The inspection protocols and full report of the manufacturing order are generated automatically. No human intervention is required in the cell, which makes contamination impossible and guarantees the “cleanliness” of the finished part. This meets the most demanding regulations and requirements, particularly those of the FDA in the U.S.

Extreme inspection and safety levels

As we have already said, the system ensures that the blank corresponds to the part being machined right from the very start of the process. Once machining is complete, the part is checked and validated, both in terms of its dimensions as well as its shape, by comparing it to the 3D model saved. If the part is correct, laser marking is performed and verified immediately afterwards. If everything is correct, the robot places the part in the magazine of machined parts. Any non-compliant parts are placed in a “drawer” and may be extracted from the cell. Monitoring of the production and management process is constantly documented. And the complete report, sent directly, is available on the programming workstation. All access points to the various components of the production cell are secure and any interventions on or access to the components are dependent on the accreditation levels of the various employees.

Optimized cycle times

When installing this type of integrated production cell, the cycle times of the various machining, inspection and handling operations are scrupulously analyzed in order to balance the assembly and avoid “bottlenecks”, which would slow down the process. Furthermore, in the event that a machining center encounters problems, it may simply be placed in quarantine. The entire process continues during maintenance work on the stopped machine. The cell is designed to work 24/7.

Preventive maintenance and ease of use

The entire production system is managed by an access rights system which allocates various skill levels to employees using it. It is controlled using a large touchscreen and, if the priority in the production queue needs to be changed, the order of parts to be machined can be modified simply by dragging and dropping them on the screen. To ensure faultless operation throughout the cycle, the preventive maintenance aspects are integrated. There are planned frequencies, for example to inspect filters every twenty hours. Any machine downtime is used to perform preventive maintenance operations involving replacement of any components which have exceeded 90% of their planned service life.

Operators are trained by Willemin-Macodel. Most users responsible for ensuring the correct operation of the machine and its supply and unloading can have a relatively limited skill level.

Integrated standard solutions

Willemin-Macodel uses two components to develop its integrated production solutions: its standard machines, guaranteeing processes which are proven in terms of their robustness, and its extensive knowledge, acquired over many years, in the provision of robotized systems and state-of-the-art automation. Throughout its evolution, our production vision has therefore resulted in a clear commitment both for ourselves and our customers: the first part produced must be correct. This testimony of faith, as it were, encourages us each day to improve the quality of our machines as much as possible. At Willemin-Macodel, it is not uncommon to see process capabilities achieve a cpk of 1.67.

Only one personal contact

To integrate various activities, as in the cell shown above, it is necessary to master numerous complementary skills. This is why we started this article by stating that the company had changed business direction. The customer purchases a turnkey solution and everything needs to operate properly and in harmony. Willemin-Macodel takes responsibility for everything, including the process. In the event of any questions, a single point of contact handles the subject in its entirety.

An assembly with constant dialogue

But what is really new here? The machines are known, as are the systems and peripherals.

In reality, it is particularly the communication and synchronisation between the various components that have required the greatest work and add value to the assembly. The control system receives thousands of signals from numerous sensors active throughout the process and it is our machining experience, built into the intelligence of the cell, which makes the difference. Today, all of Willemin-Macodel’s machines are designed and developed to be integrated into such cells, and we are looking into the possibility of associating them with other types of machines, for example to ensure all machining possibilities such as turning, milling, grinding or finishing.

The main problem is not technical

To implement an integrated machining solution of this type, it is necessary to understand the business and the needs of the user. Without this, it is impossible to adapt the cell in a satisfactory way. The work must therefore be performed in collaboration with the customer to create the solution together. Not only are production, inspection and marking tailor-made, but the entire reporting process is developed to match the user’s desires and constraints exactly. The automatic production of single parts “just in time” is now possible

solution finder

solution finder