15 April 2019

From the machining center to the complete automated 4.0 solution

At EMO, German and international customers can discover how Willemin-Macodel creates Swiss made custom machining solutions, highly competitive and meeting all types of needs.

Every two years, companies from across the globe, seeking new solutions, travel to Hanover (and sometimes Milan) in the hope of discovering how to improve their production.

The trip to this major exhibition, which brings together over 2000 exhibitors and almost 150,000 visitors, must be planned very carefully: it is impossible to see everything!

One of the stands is not to be missed! For those who want to rationally produce complex polyhedral and/or precision parts, a visit to Willemin-Macodel (hall 027, stand E46) is vital. Denis Jeannerat, our Technology Director, provides an insight here.

Four high-tech machining centers and a new business

Although our expertise will be represented by four ultra-high performance machining centers, it is specifically also our new business that visitors can discover at EMO. “This idea of a new business direction must be fully understood” explains the Director. “The integration of complete machining solutions for our customers is becoming an increasingly important aspect.

This is why we are not only manufacturers of machines but also integrators”. This is the reality. The machines are no longer just about being high-performance, with an attractive design and ergonomics at a competitive price. They must be able to communicate with the workshop and be integrated into an automated digital production flow. Here are the basics about the products to discover.

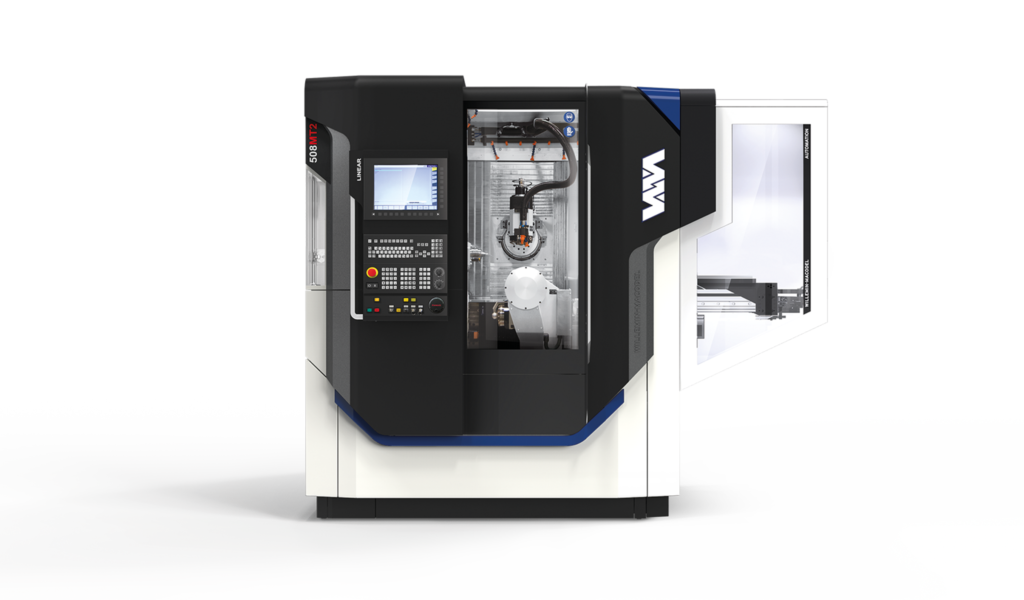

508MT2 X1000 high-precision machining center

Designed to manufacture complex parts from bar stock or slugs up to 65 mm in diameter, this machining center is equipped with a pivoting powered spindle fitted on a B axis, a high-precision A axis spindle-divider, a powerful turning turret with 12 positions equipped with fixed and rotating tools, and a multi-functional secondary operation station comprising a tailstock center, a vice and a counter-spindle.

Therefore “the 508MT2 X1000 enables turning, milling and grinding operations to be performed in a very flexible manner”, states Mr. Jeannerat.

The milling spindle has a rapid tool changer and can achieve 42,000 rpm.

But the real advantage of this multi-process center is that work can simultaneously be performed at the front and back of the workpiece. The machining capacities are identical on both sides. The operating procedures are simplified and productivity significantly increased. The objective is for the part to be always completed on the machine. A parts recovery device completes the picture: “Of course, the 508MT2 X1000 comprises integrated robotization and automation”.

508S2 high-precision machining center

The 508S2 machining center is equipped with a vertical powered spindle which can mill up to 42,000 rpm, as well as a dual rotary divider facilitating turning operations on the C axis up to 4000 rpm. Designed to manufacture complex high-precision prismatic parts, it has been developed to ensure excellent positioning accuracy: “The type of parts that we produce on this machine are always intended for an assembly. The bearing face and centering must therefore be extremely precise. It has been developed for this purpose! “.

Willemin-Macodel’s machining centers are extremely high precision tools. Their industrialization has gone one step further to ensure a robustness of the processes that is uncompromised. But they remain open to customization: the 508 S2, for example, is available with Heidenhain, Siemens or Fanuc controls, depending on the user’s preferences. The supply and unloading of parts can also be integrated into a fully automated solution.

308S2 high-precision machining center

Initially designed for Swiss watchmaking, the 308S2 center is dedicated to machining small complex prismatic parts. It is equipped with measuring scales, direct motors, a new 60,000 rpm spindle and a very large B axis.

This creates a machine with five axes offering exceptional machining capacities at a very attractive quality/price ratio! To guarantee the turning functions on the C axis, the spindle has been designed to achieve rotational speeds of 4000 rpm.

Ultimately, the 308S2 is a real hub of technologies; it is a clever solution from the very beginning of the design process right through to industrialization with an optimized price/performance ratio.

701S high-precision machining center

The 701S machine is the first machining center to truly make full use of the dynamic control and rigidity offered by delta type kinematics. Its inverted design and machining by interpolation defy the usual production and manufacturing methods. Its unique flexibility enables parts to be manufactured in very small runs.

The basic machine, comprising a magazine of blanks of 12 to 14 posts, can be fitted out with a robotized solution as an option, particularly suited to medium and large production runs with a sizeable work list, as well as presetting, deburring, cleaning or inspection stations.

Custom automation…

The automation notion can cover numerous different concepts. For Mr. Jeannerat, Willemin-Macodel has the following vision: “We offer all degrees of automation, from simple loading robots to the complete cell comprising loading, unloading, machining, finishing and inspection. Our aim is to implement a machining solution which perfectly meets our customer’s requirements, in terms of machining as well as handling, traceability or inspection.

Thanks to today’s technology, it is perfectly possible to produce single parts or very small runs with the same advantages of rationality and productivity as during large production runs. This performance is facilitated by the flexibility and robustness of our solutions”.

…and not using Grandma’s robot

“Automating does not simply mean using a robot to perform an identical operation. It involves taking stock with the customer, proposing a comprehensive solution which has never before been conceived and offering much more”, concludes the director.

For example, Willemin-Macodel has designed a complete production chain intended for the medical field incorporating management of parts, batches and tools with complete traceability. It even has an integrated printer to produce the reports needed by the customer! Another of our cells is equipped with cryogenic machining technology, guaranteeing contamination-free machining.

“Machine manufacturer” is a profession that is evolving fast. Willemin-Macodel’s presence on stand E46 in hall 027 of the EMO in Hanover will undoubtedly offer the best way to understand how. You will find us there from 18th to 23rd September.

solution finder

solution finder