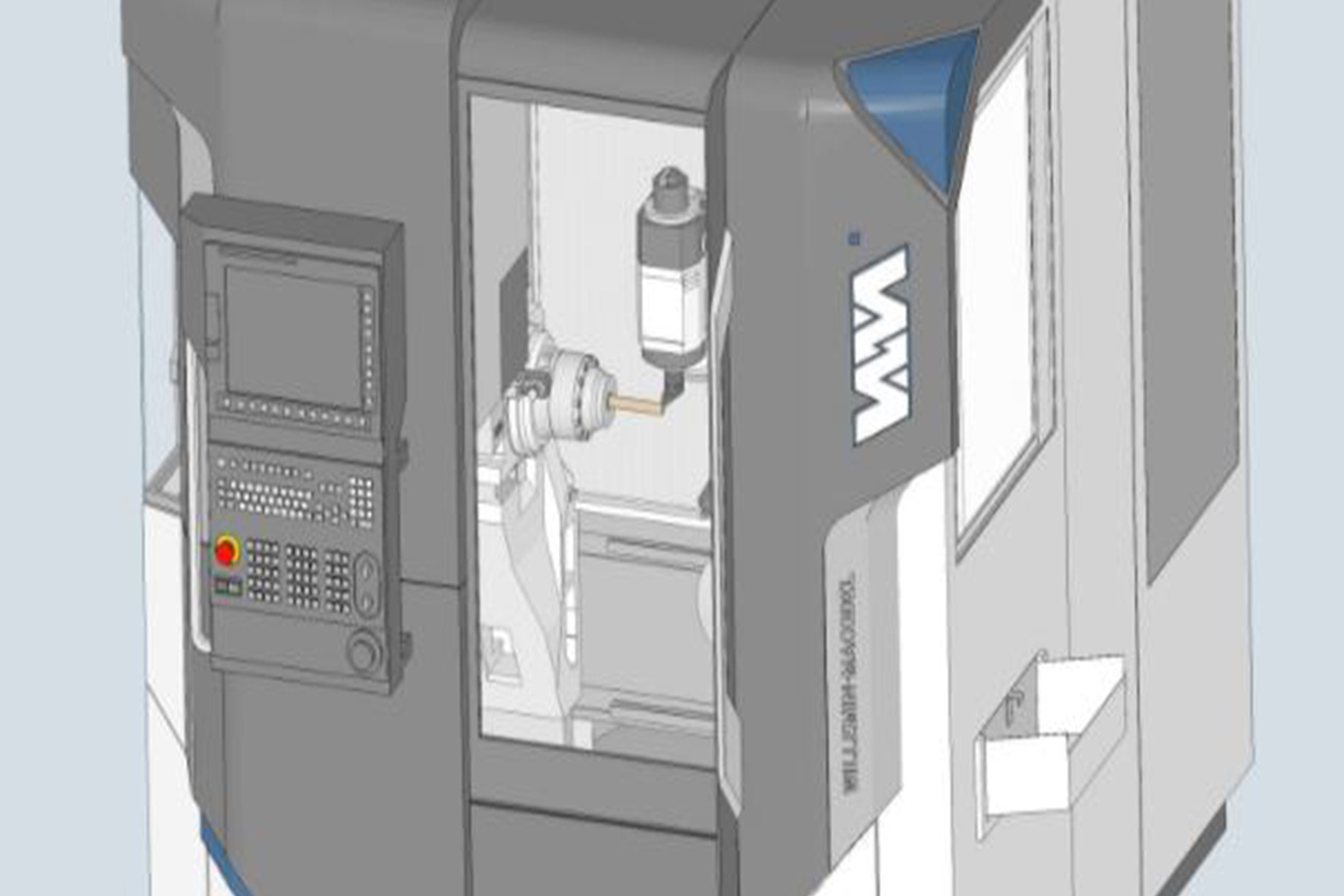

main characteristics

- Powered spindle, 50 - 20,000 rpm

- HSK-A63 interface

- B axis angular movement -10° to +100°

- Feed rate on linear axes X Y Z of 20 m/min

DESCRIPTION

The 528JIG machining center has been designed for high precision machining of complex parts within a maximum cube dimension of 350 mm per side, requiring surface finishes of the highest quality. The high-precision rotary divider with direct drive and the large capacity tool magazine (up to 180 tools) combine to form a production unit which offers high levels of performance, flexibility and productivity. The compact construction of this machine minimizes its footprint.

Equipped with an HSK-A63 interface, the pivoting powered spindle with highly dynamic synchronous motor is fitted on the B axis.

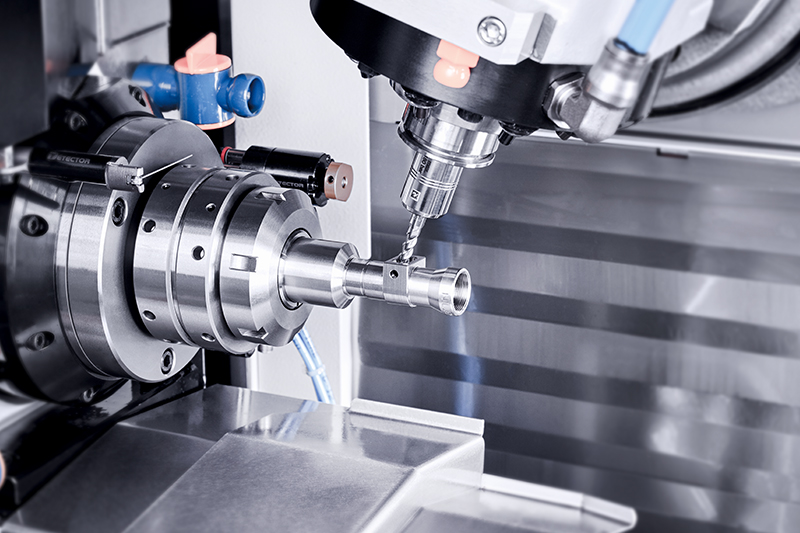

Willemin-Macodel's expertise and experience in the design and production of ultra high precision machines are essential requirements when it comes to manufacturing JIG BORING type machining centers (boring, reaming). The geometry and quality of the machine's constituent components must be perfect. Only a super precision machine tool that offers almost perfect straightness, perpendicularity and positioning repeatability can be further improved by a volume calibration operation.

Other characteristics

- Powered spindle, 50 - 20,000 rpm

- HSK-A63 interface

- B axis angular movement -10° to +100°

- Feed rate on linear axes X Y Z of 20 m/min

- Standard 24-position tool magazine

- (40, 72 or 180 positions as an option)

- Tool change time 5 sec

- Central coolant programmable up to 80 bar

- Footprint approx. 9.5 m2

- High precision of X, Y and Z linear axes. Resolution 0.0001 mm. Feed rate 20 m/min, positioning uncertainty (P) 3.0 ÷m, repeatability (Ps) 2.0 ÷m

- 20,000 rpm powered spindle with HSK-A63 interface. Highly dynamic synchronous motor. Super precision hybrid bearings

- High-precision C axis vertical divider, driven by synchronous motor. Slotted Ø 600 mm plate. Rotational speed 100 rpm, positioning uncertainty (P) 3.0", repeatability (Ps) 2.0 "

- Fanuc 31i-B515 NC control console, 15" screen(Heidenhain TNC 640 as an option)

- 24-position pickup tool magazine (40-position or 72/180-position Cartesian magazine as an option)

- Various automation systems, loading or unloading of workpieces or pallets (can be adapted on the right-hand side of the machine)

- Swarf and cutting fluid recovery tray (recovery of precious metals or conveyor as an option)

solution finder

solution finder