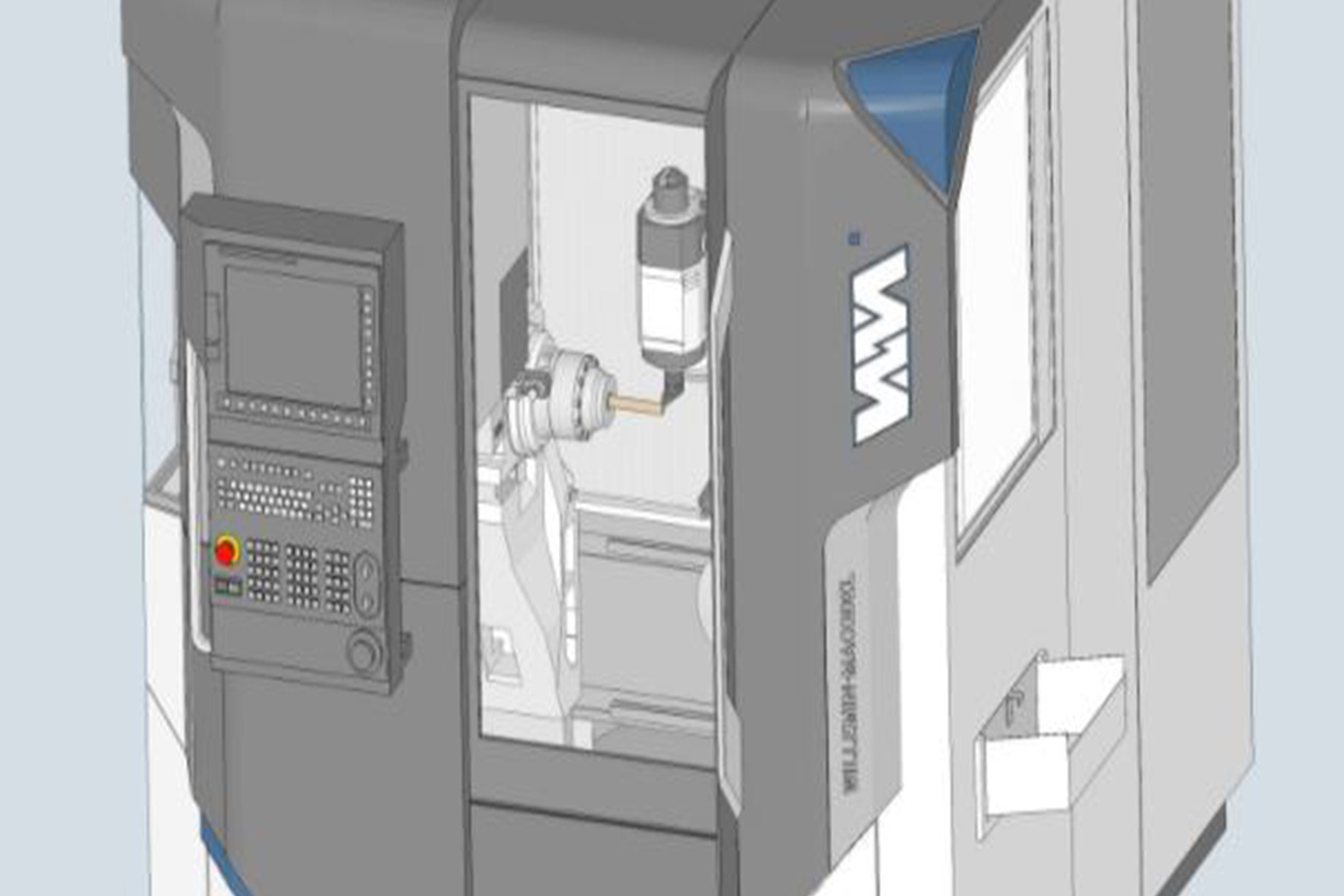

main characteristics

- 3-axis parallel kinematics, plus 1 rotational axis on the spindle

- Ultra-high-speed spindle, rotation up to 80,000 rpm

- Linear axis acceleration 10 m/s2 during machining

- Feed rate on linear axes X Y Z of 72 m/min

- Small footprint, approx 1 m2

DESCRIPTION

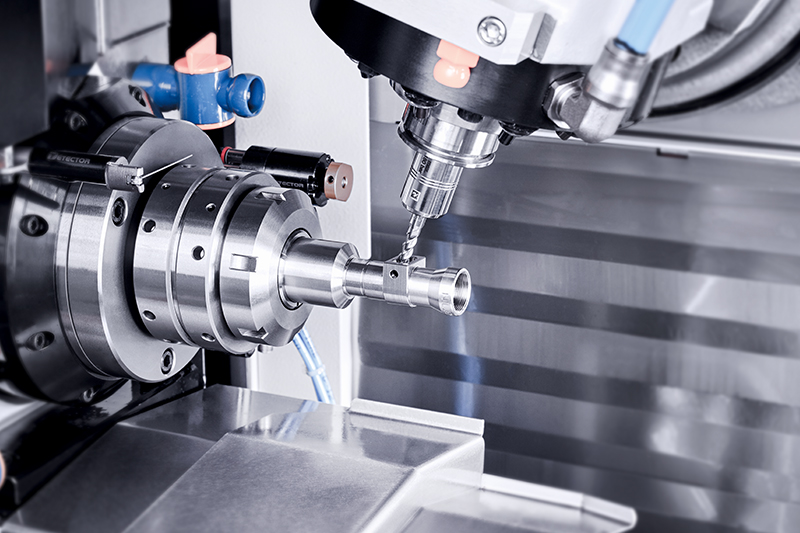

The 701S machine is the first machining center to truly make full use of the dynamic control and rigidity offered by linear delta type parallel kinematics. True to Willemin-Macodel's reputation, this machine delivers ultra-high-precision machining conditions using ultra-high-speed machining technology.

The 701S machining center, the very essence of innovation, offers unrivalled precision and dynamic control for watchmaking and micro-machining applications. The DELTA dynamic control pushes the boundaries of traditional machining to offer sub-micron precision and nanometric surface finishes, thanks to a combination of low weight in motion, high resolution measuring scales and ultra-fast calculation of the control loop via the PC numerical control.

The ultra-high performance powered spindle has been specially developed to fit seamlessly with the kinematics on the 701S machine. It meets the most stringent requirements in terms of precision and dynamic balancing. The tools are directly fixed on the powered spindle, with no need for a tool holder. Its maximum rotational speed is 80,000 rpm.

The 701S is ideal for cutting-edge industries such as watchmaking, micro-moulding and high-precision micromechanical subcontracting.

-

Ultra-high-speed fixed spindle, 80,000 rpm

- Delta architecture, 3 articulated arms without play and without friction

- Ergonomically designed CNC with ISO programming and PC interface

- Detachable tool magazine with up to 72 positions

- Pallet magazine with 12 positions

- Swarf management with built-in filtration

solution finder

solution finder