main characteristics

- Milling up to 42,000 rpm (optional)

- Powered spindle, 0 - 30,000 rpm in 0.8 s

- 400 x 280 mm slotted table

- Acceleration of X Y Z linear axes, 8 m/s2

- Rapid feed rate of X Y Z linear axes, 40 m/min

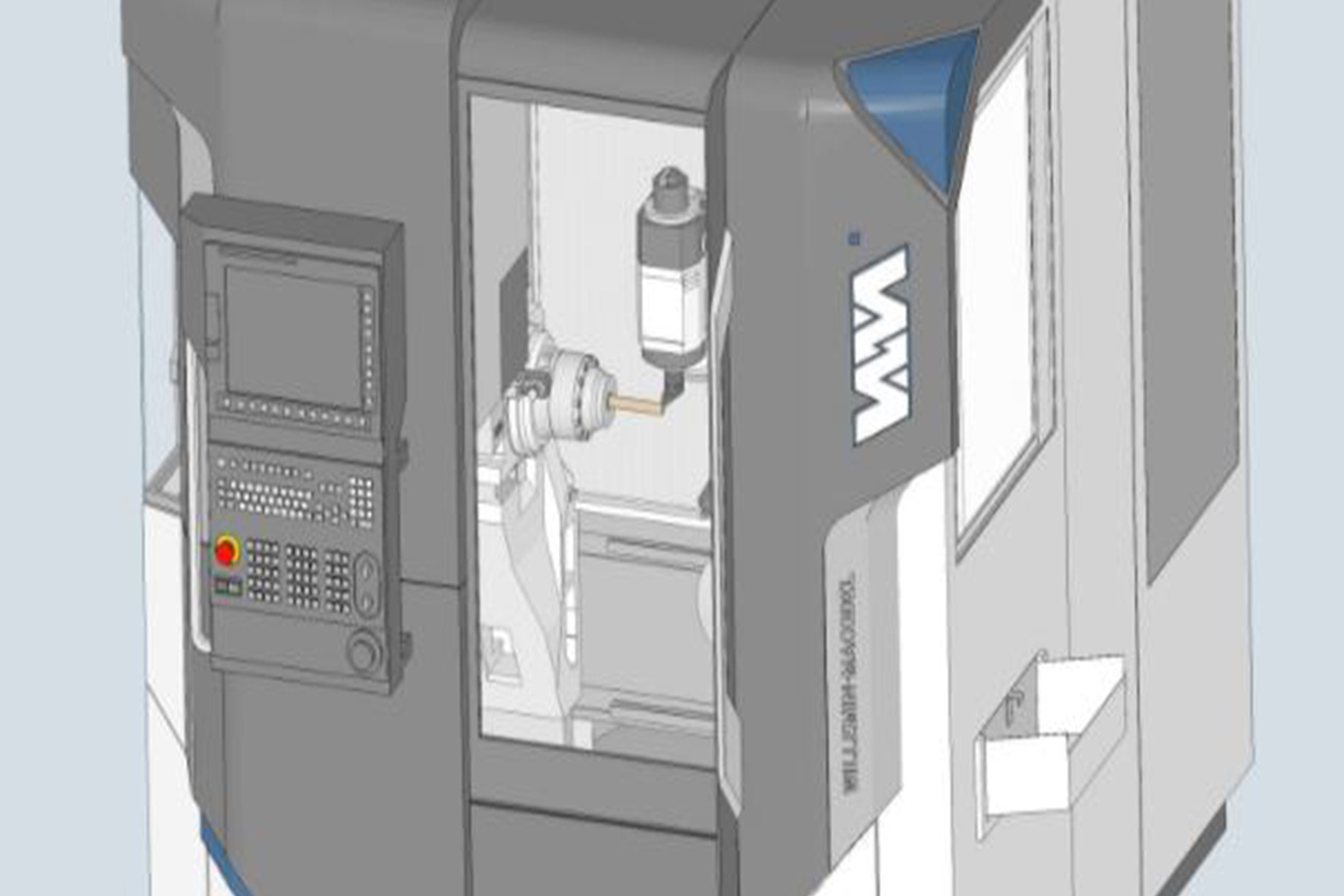

DESCRIPTION

The 401s2 is a 3-axis vertical spindle machining center designed for machining high precision main plates and bridges for the watchmaking sector.

Generally, its design enables complex parts to be machined within a surface area up to 250 x 200 mm.

This machine guarantees excellent surface finishes and high precision machining, particularly in terms of stability of the z-axis dimensions.

The range of equipment, such as tool magazine, tool measuring, part inspection, clamping devices or manipulators, provides great flexibility for the production of small or medium part series.

Benefiting from the latest technological developments and willemin-macodel's comprehensive expertise in high-precision machining, the 401s2 is perfect for cutting-edge industries such as watchmaking and high-precision precision contract machining.

Other characteristics

- Milling up to 42,000 rpm (optional)

- Powered spindle, from 0 – 30,000 rpm in 0.8 s

- HSK-E40, HSK-A40 or Capto C4 interface

- 400 x 280 mm slotted table

- Acceleration of X Y Z linear axes, 8 m/s2

- Rapid feed rate of X Y Z linear axes, 40 m/min

- Tool magazine up to 96 tools

- Tool change time 0.8 sec

- Optional coolant through spindle programmable up to 80 bar

- Footprint approx 2.8 m2

-

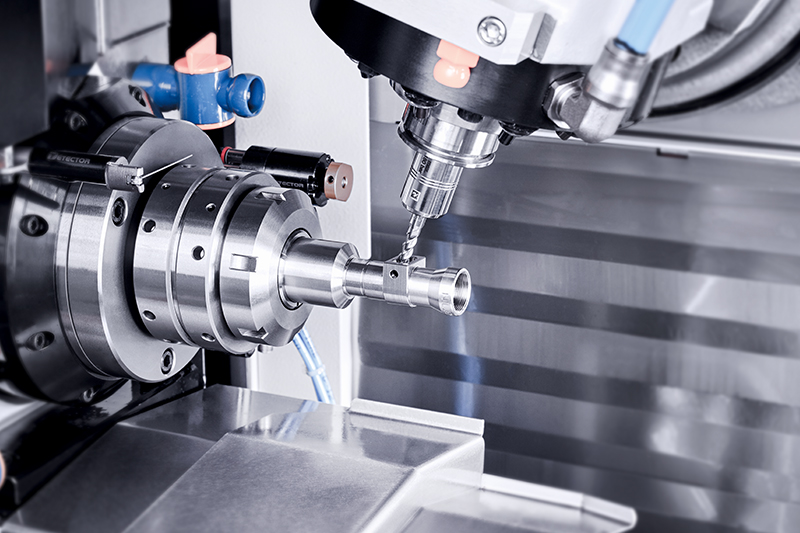

Powered spindle 30,000 rpm with HSK-E40, HSK-A40 or Capto C4 interface (optional 42,000 rpm milling)

- 400 x 280 mm slotted table T slots (3x) 12-H8, center-to-center distance 80 mm

- Fanuc Oi-MF PLUS iHMI PRO CN control panel, 15" screen with integrated PC. Also available with Heidenhain TNC 640 numerical control

- 48-position tool magazine with quick changer (72 or 96 positions optional). Tool breakage detection in masked time

- Various automation systems, loading or unloading workpieces or pallets (can be adapted on the right-hand side of the machine)

- Swarf and cutting fluid recovery tray (swarf tray with drawer, recovery of precious metals or conveyor optional)

solution finder

solution finder